Two on-board units (OBUs) for contactless toll collection used by millions of trucks and cars, TRP-4010 and OBU-5310 from Kapsch TrafficCom are the first hardware components of tolling solutions that comply with the EU Taxonomy Regulation regarding climate change. The analysis also included a comparison with competing products of the same functionality. The result: both OBUs are the smallest, lightest and most sustainable in their class.

Sustainable toll hardware

TÜV AUSTRIA has certified that the calculations and reporting of the respective carbon footprints of both products meet the requirements of the EN ISO 14067:2018.

The Product Carbon Footprint according to ISO 14067 is the most established method for determining the climate impact of a product. It takes into account the carbon footprint at every stage of the product life cycle. This includes raw material extraction, design, production, transport, use and end-of-life management of the individual units.

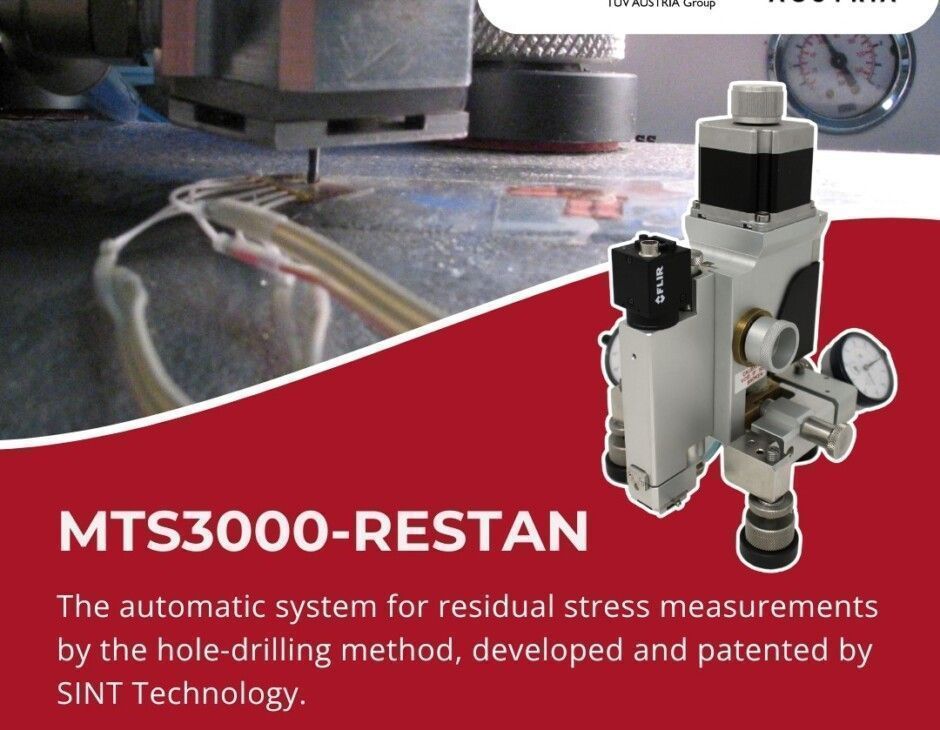

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

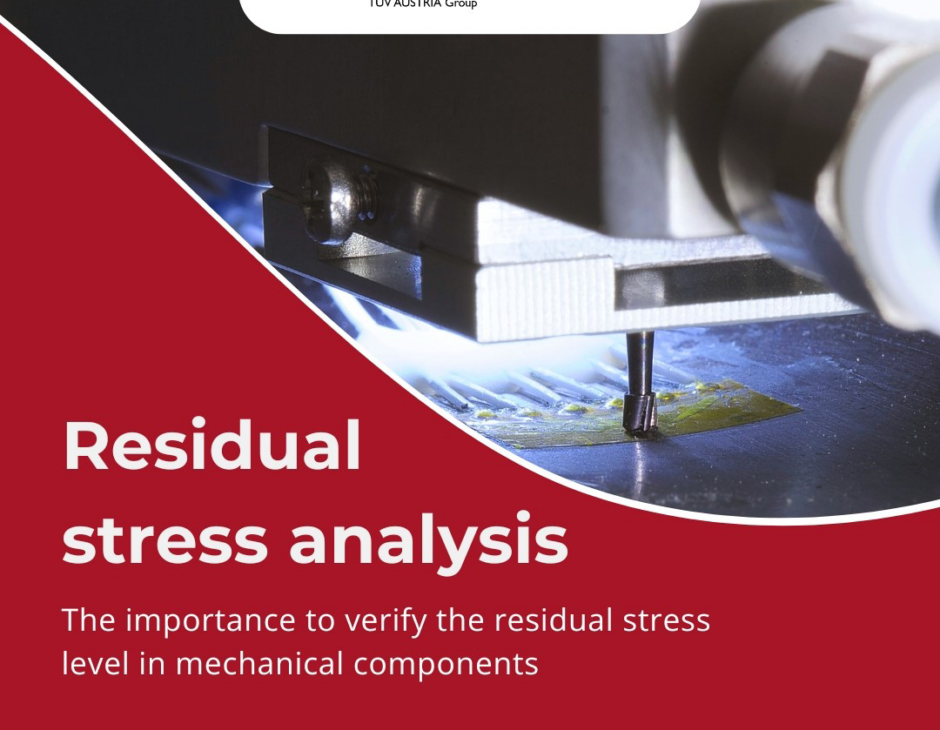

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

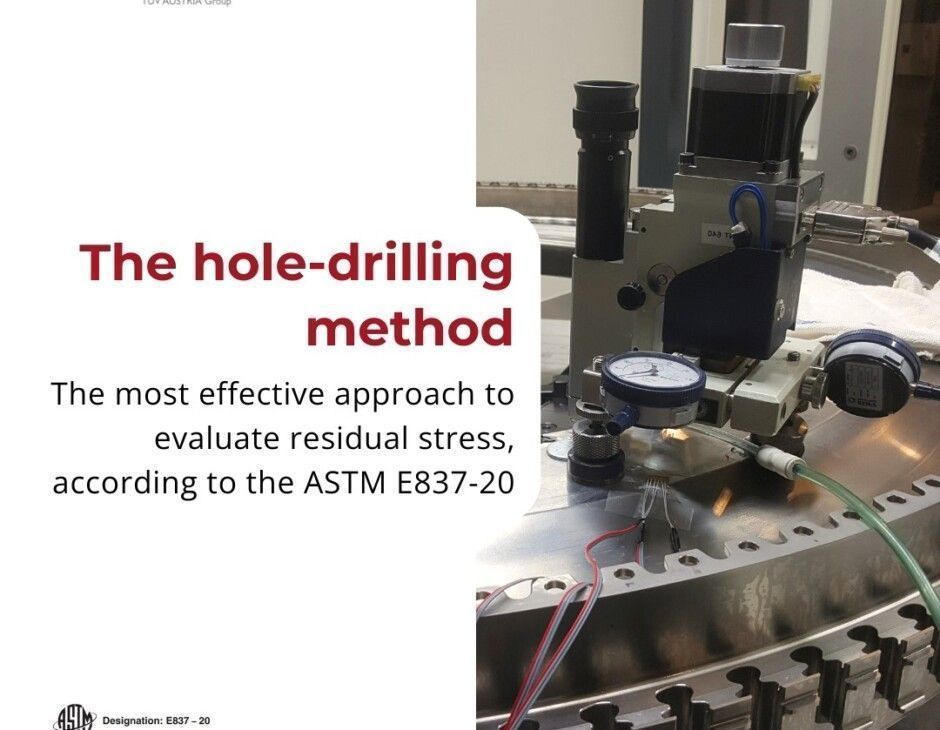

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.