Revolutionizing Functional Safety with Hardware Independent Safety

SIListra Systems GmbH, a highly specialized software company, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA group, announced their strategic partnership to improve the safety development of embedded systems. The collaboration brings together SIListra’s cutting-edge software tool, the certified SIListra Safety Transformer, and innotec expertise in functional safety solutions, aiming for a holistic approach to functional safety.

SIListra Systems, renowned for its pioneering technology, offers the SIListra Safety Transformer, a tool designed for deployment of coded processing within the field of functional safety. This revolutionary approach sets new benchmarks in the safety area in different sectors, including industrial, automotive, railway, and medical, reducing costs and complexity and enabling a higher degree of safety.

Complementing SIListra’s groundbreaking solution, innotec stands as a premium consulting company in supporting customers with all matters regarding functional safety and the related processes. Leveraging their in-depth knowledge and experience, innotec delivers comprehensive consulting solutions tailored to meet the diverse safety needs of different industries.

Through this collaboration, both companies committed to redefine safety paradigms, offering tailored and advanced solutions and supporting customers in the deployment of safety solutions based on coded processing technology. For the customers involved in safety development this means direct access to technology and consulting providers which speak the same language when it comes to safety. As a result, the entire approval process as well as all safety engineering activities can be optimized and sped up.

“The collaboration with innotec signifies a major step forward in ensuring safety excellence,” said Jens Schindler, Managing Director at SIListra. “Together, we aim to support our common customers in the best possible way, deploying functional safety solutions based on coded processing technology.”

“We are excited to join forces with SIListra in revolutionizing the safety approach for our common partners and customers,” commented Claudio Gregorio, CEO at innotec. “Our combined expertise will empower clients to navigate the complex landscape of functional safety with confidence. This collaboration is crucial to deliver innovative safety solutions, setting a new benchmark for the functional safety in the embedded industry.”

More information about the synergies created through this collaboration from a technical perspective can be found at Technical Report.

For media inquiries or further information, please contact:

Jens Schindler, info@silistra-systems.com, +49 351 418 909 34 and Claudio Gregorio, info@innotecsafety.com, +49 711 722 336 144.

—

About Innotec

innotec GmbH is a consulting company specialized in functional safety, machinery safety and cybersecurity. Established in 1998, innotec GmbH advises companies on all matters regarding safety technology and the related processes, with the primary goal to enable them to realize projects as swiftly and cost-efficiently as possible, and making no compromise on safety.

About SIListra Systems

SIListra Systems GmbH, headquartered in Dresden, is an innovative, highly specialized IT technology company that is a spin-off of TUD Dresden University of Technology founded in 2012. The focus is primarily on special software solutions and their implementation in development tools for use in the field of functional safety as well as the automation of safety-relevant applications. With the SIListra Safety Transformer, SIListra Systems offers a certified product solution in accordance with the safety standards IEC 61508, ISO 26262, ISO13849 and IEC 62061. All development and project employees are certified as Functional Safety Engineers, Professionals or Experts (FSCP). More information about the company is available at silistra-systems.com.

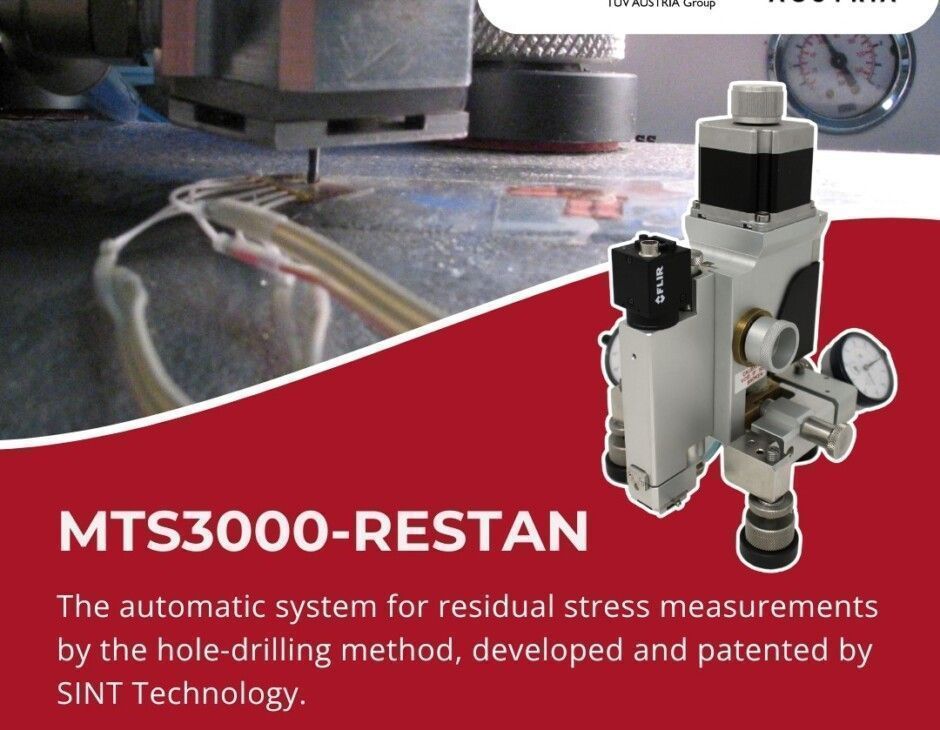

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

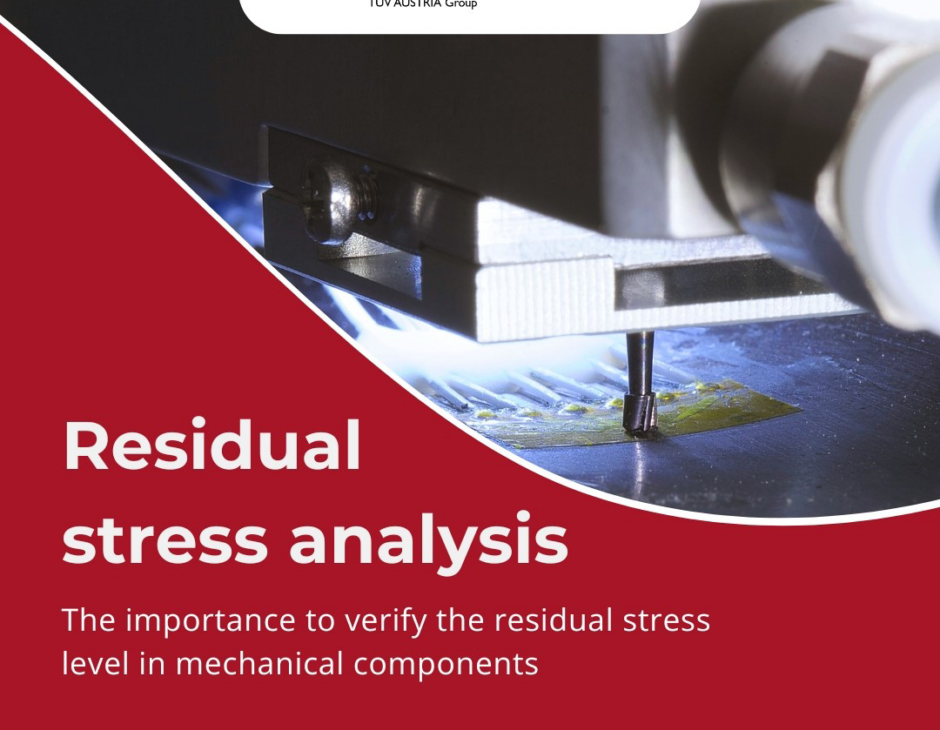

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

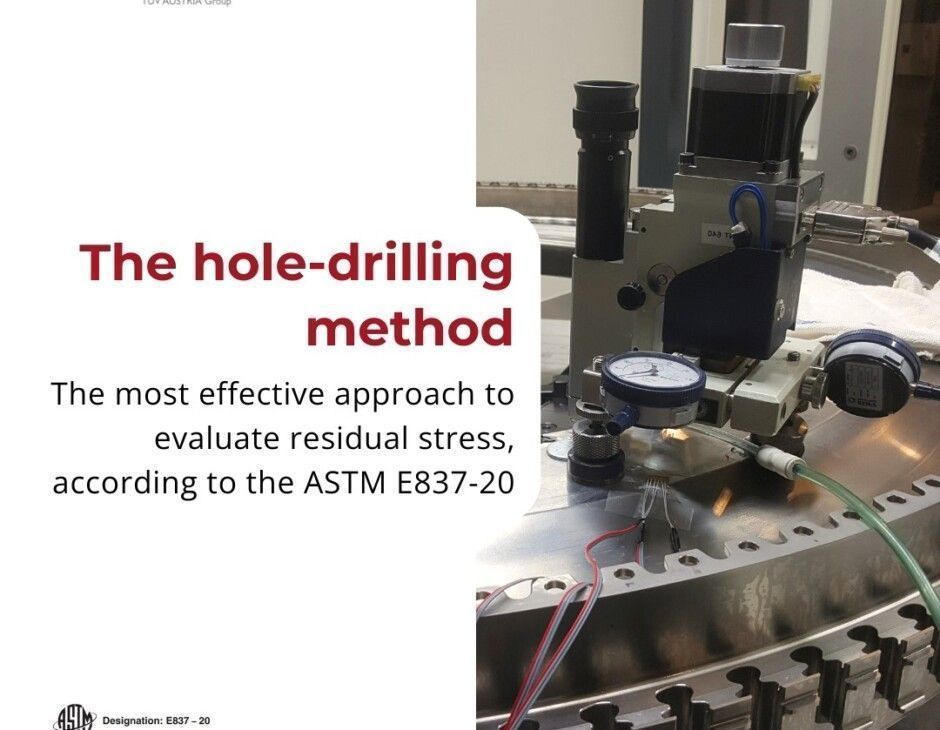

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.