Europe’s highest slide has been opened at Vienna’s Danube Tower. Safety is taken care of, the slide has been thoroughly tested by TÜV AUSTRIA with regard to all safety-relevant aspects.

TÜV AUSTRIA can already look back on extensive experience in testing long dry slides and the experienced test technicians therefore know what needs to be paid close attention to during the inspection. But the installation height of this slide, with its starting point at a height of 165 metres, was also unique for our inspectors. The extraordinary attraction takes adrenaline junkies down to the viewing platform at 150 metres, with the outside of the spiral located outside the platform.

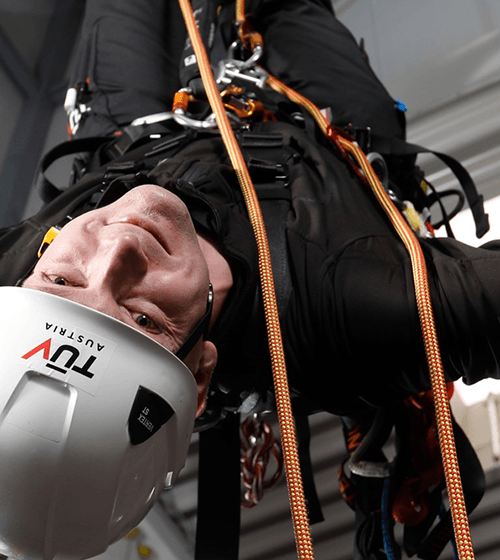

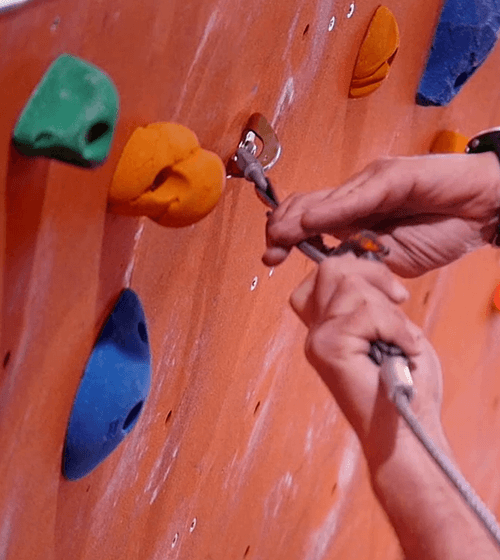

Equipped with a specially coated slide mat, the TÜV AUSTRIA test technician examined the slide in detail. This mat with a very high coefficient of friction allows the inside of the slide to be inspected without moving unintentionally.

Successfully meeting the requirements

The requirements and special features of the realisation of this work of art were remarkable. Authorisation was required from the authorities, as the Danube Tower is a listed building. The slide was installed with the help of a helicopter and industrial climbers and can also be used by visitors with limited mobility using a specially designed access aid.

All safety-relevant aspects were considered in detail during the acceptance test. For example, the top of the slide, which is clad in transparent polycarbonate, provides a special thrill and gives the riders a breathtaking view. Special fire protection measures had to be taken into account here, as did the lighting, as restrictions of an aeronautical nature apply.

After detailed testing, the slide at the Vienna Danube Tower was approved by the TÜV AUSTRIA test engineer to offer visitors a safe and fascinating experience.

“The cooperation with TÜV AUSTRIA in the realisation of our latest attraction, the Danube Tower slide, the highest slide in Europe, was extremely professional right from the start. TÜV AUSTRIA’s expertise in this area, combined with their understanding of the specific requirements of our project, helped to ensure that our slide could be safely put into operation. We are proud to be able to offer our guests a unique and safe experience that provides a breathtaking view of Vienna,” says Hermann Krammer, Managing Director of the Vienna Danube Tower.

Tip: To be able to enjoy the unique view of Vienna during the thrilling slide, TÜV AUSTRIA test engineer Robert Terp recommends sliding twice, as you can concentrate better on the breathtaking view during the second slide.

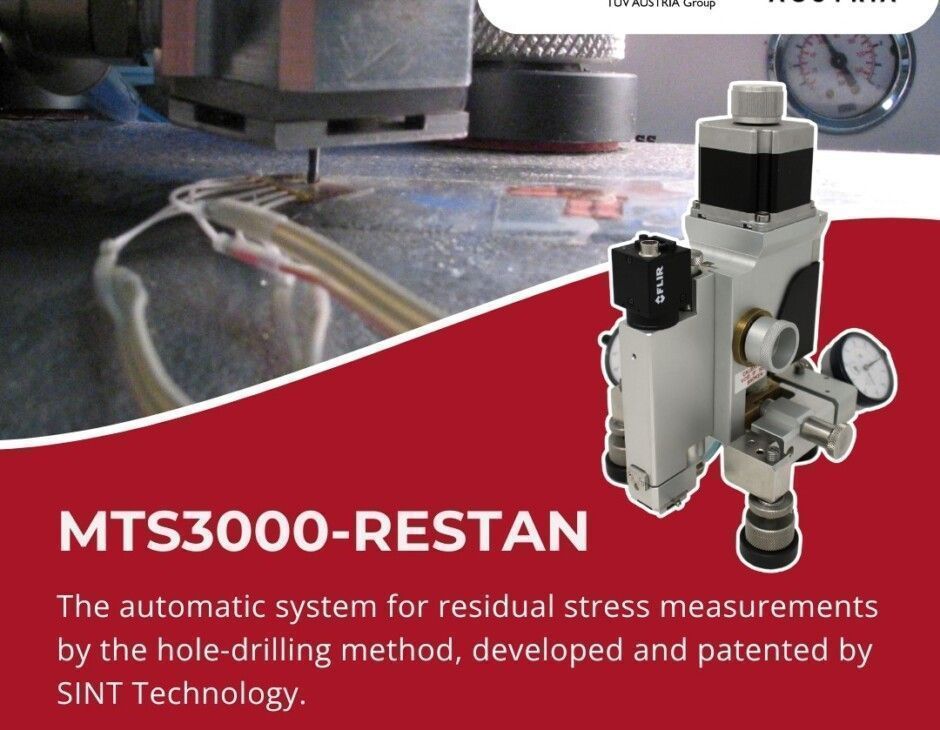

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

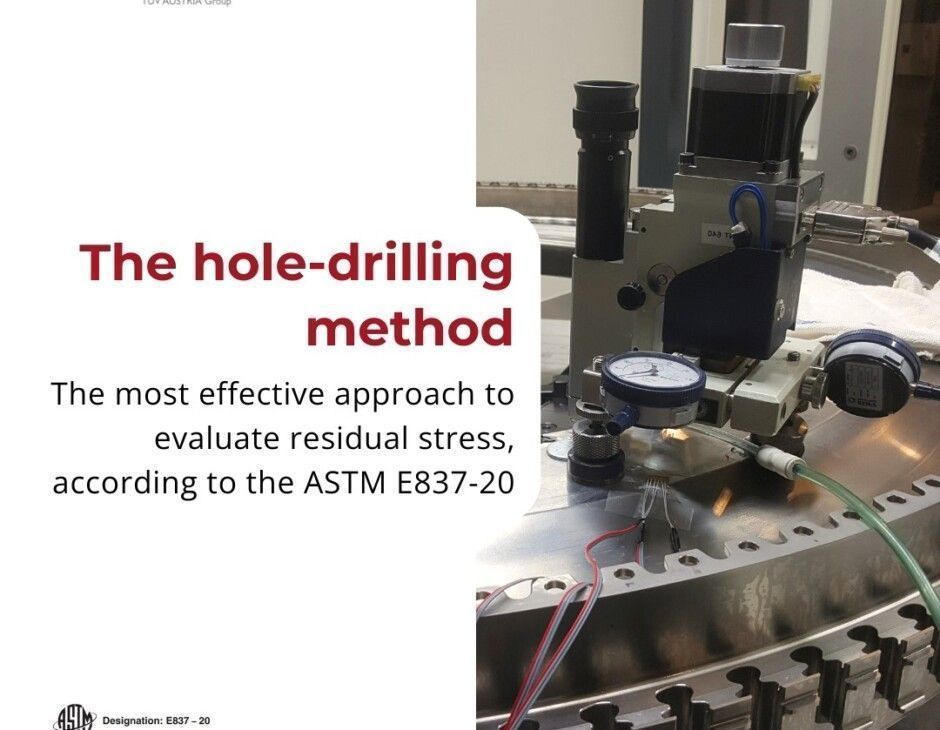

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

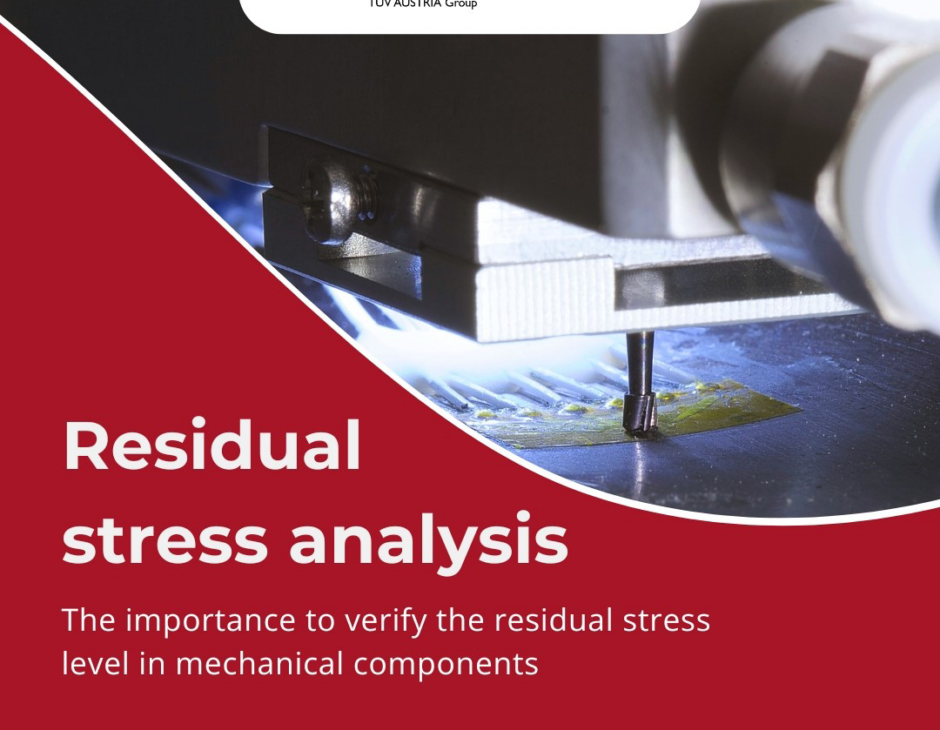

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.