Accredited and internationally established Italian certification company adds key environmental and security certification competencies to leading testing, inspection and certification organisation.

A renowned staple in international certification business, Padua-based Q.C.B. Italia SRL, which operates in the Italian territory as well as Albania, Iran and Saudi Arabia, now complements the far-reaching portfolio of TÜV AUSTRIA Group. The Austrian organisation of 55 companies in over 27 countries has been keen on providing its customers access to Q.C.B.’s specialised certification services.

Expanstion of Certification Business in Italy

Quality Certification Bureau Italia SRL, was acquired by TÜV AUSTRIA HOLDING AG as a 100% subsidiary. TÜV AUSTRIA Group’s Italy country manager Crescenzo Di Fratta exudes enthusiasm: “This organic business opportunity literally presented itself”, citing ACCREDIA accreditations for the certification of quality management systems according to ISO 9001, for ISO 14001 environmental management, as well as in the field of fluorinated greenhouse gas in compliance with EU Regulation n. 517/2014, and according to UNI 10891 and UNI CEI EN 50518 for security firms, as valuable additions for TÜV AUSTRIA’s customer base.

Former QCB owners Renato Rossi and Nicoletta Menegon look forward to establishing QCB’s specialised services in TÜV AUSTRIA’s on-going digitalisation of solutions: “It is rewarding to be inducted in the demanding TIC business, to add value to the premium services customers love TÜV AUSTRIA for”. Rossi and Menegon emphasise that although the inclusion of accreditations for Italian standards – such as UNI 10891 and UNI CEI EN 50518 for security firms – suggests a focus on Italy, QCB will be internationally integrated in TÜV AUSTRIA Group, which achieved a record revenue of €230 mio. in 2020 as one of the TIC companies to post a profit despite the crisis.

In Italy, country manager Crescenzo di Fratta’s plans for extending TÜV AUSTRIA Italia’s certification arm are afoot: “ACCREDIA accreditation, the authorization from the Ministry of Interior, the exemplary energy of QCB auditors all combine into a rich solutions tool set for existing customers”. It is another step to refining TÜV AUSTRIA Italia’s increasingly diversified portfolio that, Di Fratta points out, is suited for many business sectors. Following the inclusion of OK compost and OK Recycled certification schemes, Quality Certification Bureau therefore will not only further leverage TÜV AUSTRIA Italia’s reach but also solidify TÜV AUSTRIA Group’s role as an integrated end-to-end partner connecting technology – and living the future today.

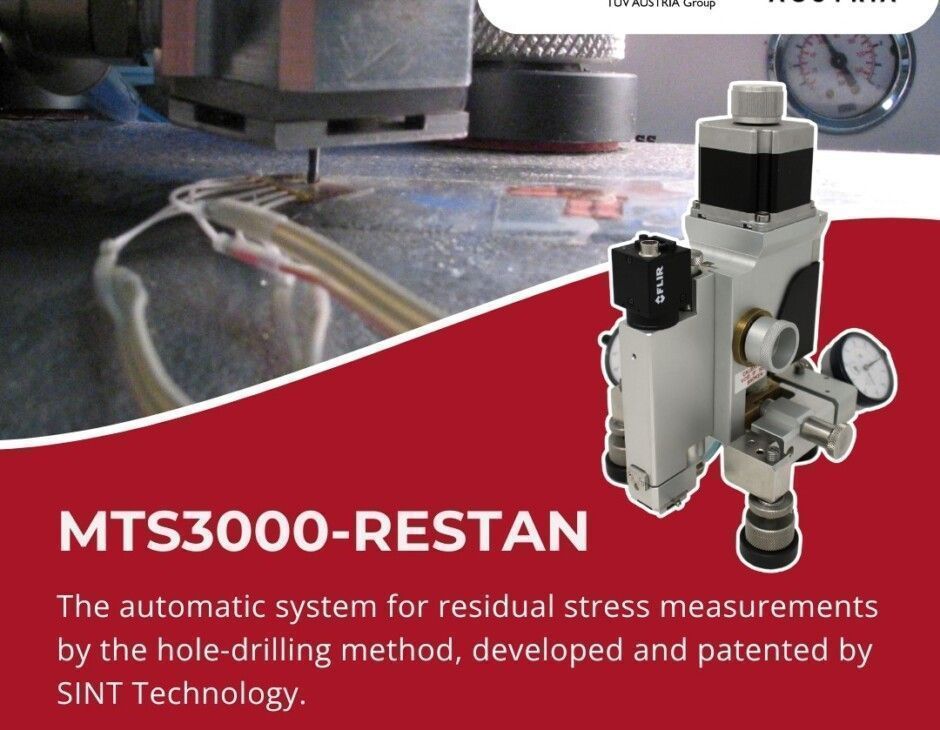

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

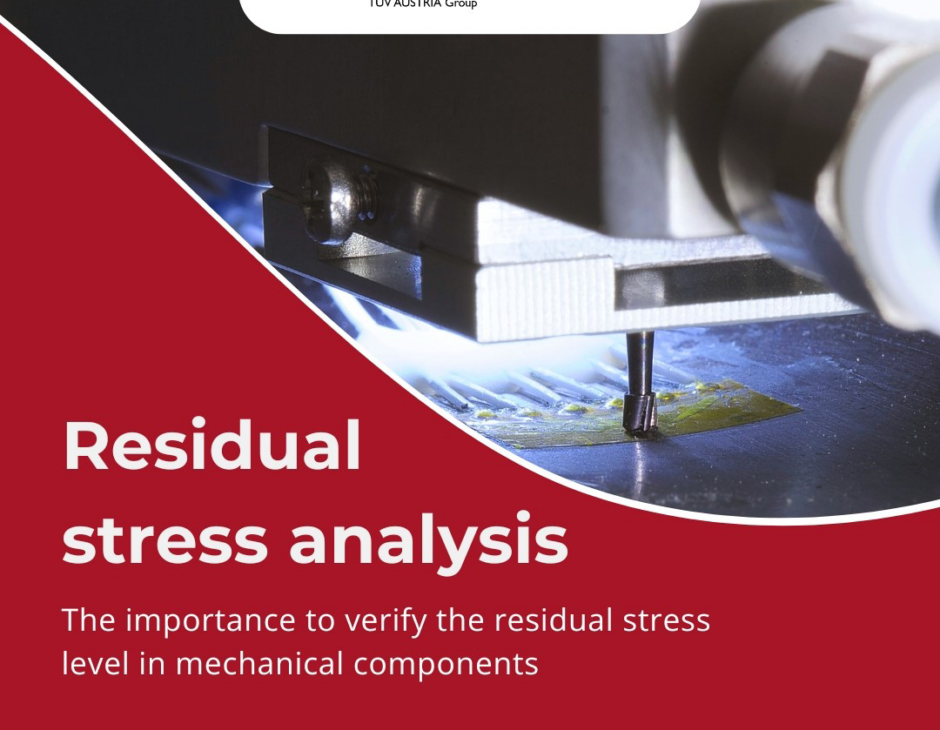

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

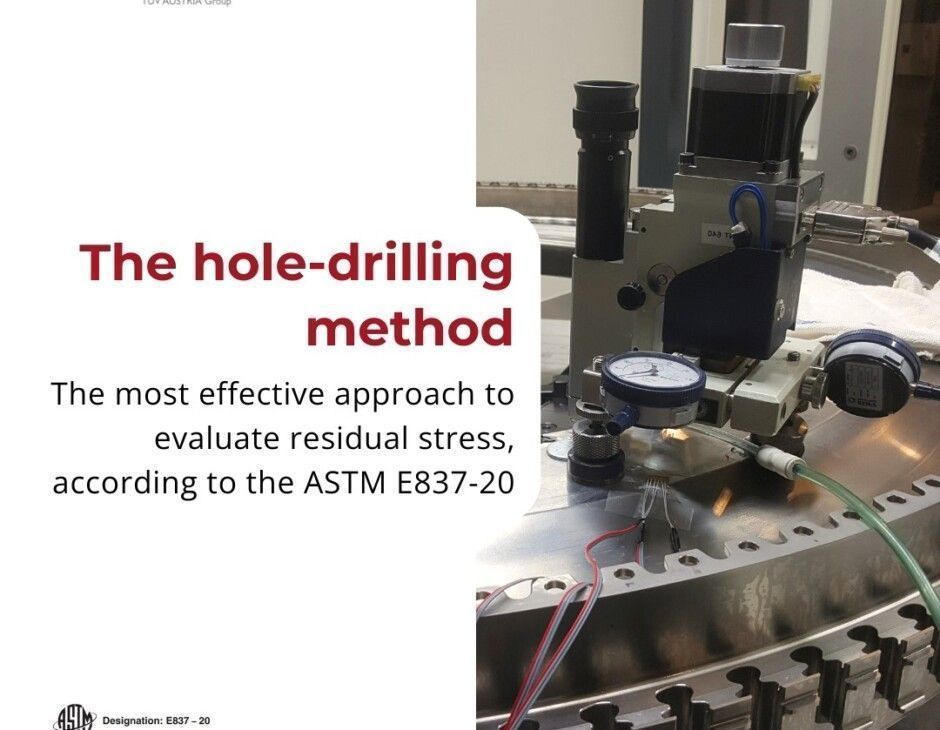

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.