The TÜV AUSTRIA Technology & Innovation Center, Vienna’s most modern testing and research centre, is taking another step towards the future thanks to the opening of the new Automotive Competence Hub. The newly constructed test hall and office building complex offers all automotive tests and inspections in combination with the existing wheel and tyre test halls. Whether vehicles with conventional combustion engines, electric drives or alternative propulsion systems such as hydrogen, the perfectly networked TÜV AUSTRIA location in the south of Vienna is at the cutting edge of technology and thus the address for testing services for all aspects of motor vehicles.

From the classic car to the ultra-modern lifting platform

For car enthusiasts, the new Competence Hub represents a significant expansion of the automotive options at the TÜV AUSTRIA Technology & Innovation Center. In addition to the testing of converted or imported cars, classic cars, small trucks and motor homes, trailers and motorbikes as well as §57a inspections, state-of-the-art lifting platforms for cars and small trucks, motorbikes including assembly pits with automatic roller cover including roll-off test bench have been implemented.

The two electro-hydraulic underfloor scissor lifts for cars and small trucks with a lifting capacity of approx. 6 t and the electro-hydraulic motorbike lift with a lifting capacity of approx. 600 kg enable all offered inspections to be carried out safely and efficiently. One platform has been specially designed for electric mobility with regard to the requirements of a high-voltage workstation. The new and ultra-modern test pit for vehicle inspections is secured by an automatic roller cover made of galvanised steel with a load capacity of 10 tonnes. A 20 t hydraulic articulated play tester and a 15 t hydraulic pit jack complete the state-of-the-art equipment of our automotive competence hub.

A compact exhaust system integrated into the prefabricated assembly pit protects TÜV AUSTRIA employees and customers from vehicle exhaust fumes at the brake test stand (integrated into the prefabricated assembly pit) by means of roof ventilation. The test hall of the Automotive Competence Hub can be conveniently accessed via four electric and radio-controlled high-speed doors (3x east, 1x west). An inserted walk-through door increases energy efficiency in the cold seasons.

The driving assistance system calibration test bench as a technical highlight

Especially after structural changes to the chassis (such as lowering, raising), the calibration of assistance systems after various vehicle conversions should not be neglected, because these systems only function properly if the chassis is also correctly adjusted. For example, the function of camera-based assistance systems such as intelligent light systems depends on correct calibration. In the case of structural changes to the chassis, the adjustment of the headlights and the calibration of the assistance systems must be checked in most cases after the chassis check (measurement). TÜV AUSTRIA now offers this service thanks to the new calibration test bench and will optionally include this information in the expert opinion in the future – an additional offer for our customers.

Our customers can now comfortably follow the testing procedure on their high-quality vehicles from the modern and comfortably equipped customer waiting area through the generously designed glass pane of the connecting door between the customer waiting area and the testing hall.

Thanks to the ideally utilised spatial conditions, the state-of-the-art equipment and the optimal networking with other TÜV AUSTRIA solution offerings at the Technology & Innovation Center, e.g. the EMC hall with the possibility of performing EMC tests on vehicles and vehicle components, the Automotive Competence Hub is the perfect contact point for all testing and inspection activities on motor vehicles.

#wedo: Automotive test methods

The TÜV AUSTRIA #wedo expert videos provide a detailed insight into our wide range of solutions in the field of automotive testing procedures:

Contact:

Dipl.-HTL-Ing Christian Kubik, MBA

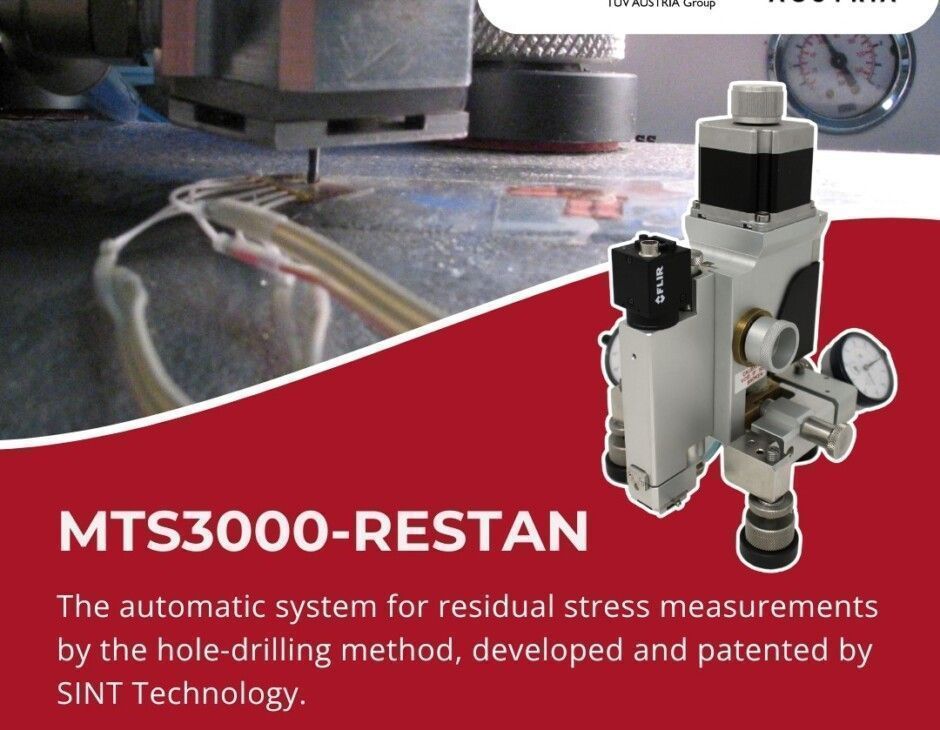

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

SINT Technology

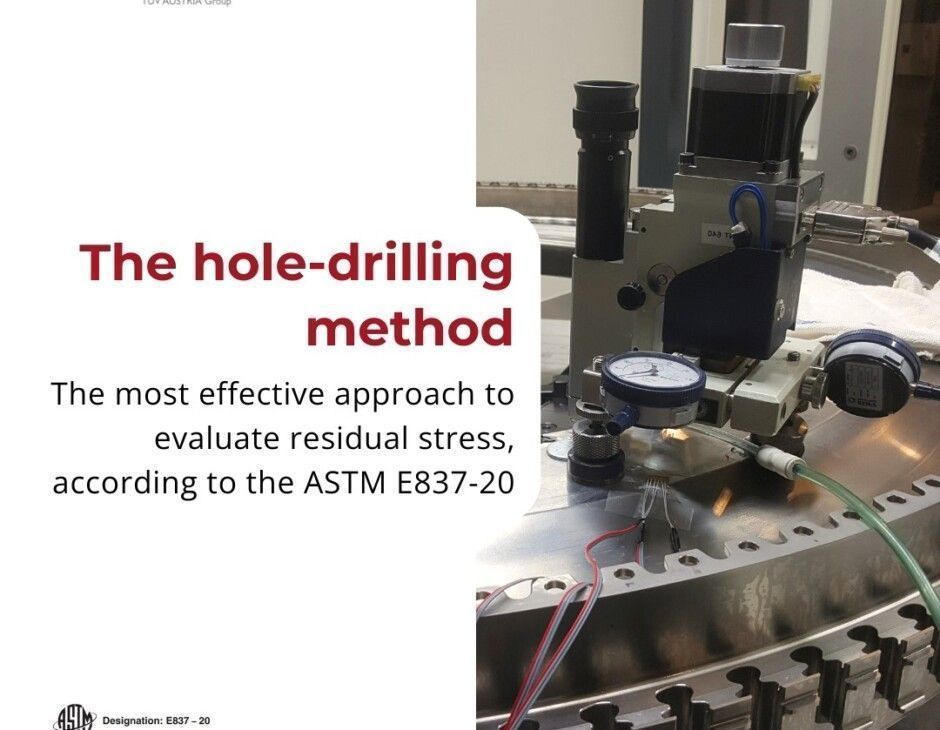

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.