The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Our objectives and contributions were manifold: TÜV AUSTRIA uses the Canton Fair as a platform to showcase our certification, inspection, testing and technical services, and to demonstrate our expertise and competence to global customers.

Participating in the Canton Fair helps TÜV AUSTRIA to expand the international market, especially in China and its neighbouring regions. This exhibition attracts a large number of international visitors, many of them are interested in finding products and services exported from China. This also helps us to identify new business opportunities and partners.

The Canton Fair provides a platform for professionals from various industries to communicate and cooperate with each other, covering a wide range of product lines. TUV AUSTRIA uses this opportunity to negotiate business cooperation with potential customers and partners at the booth.

Participating in the Canton Fair can also help TÜV AUSTRIA understand the latest market trends, changes in demand and competition, and provide reference for the development of market strategies.

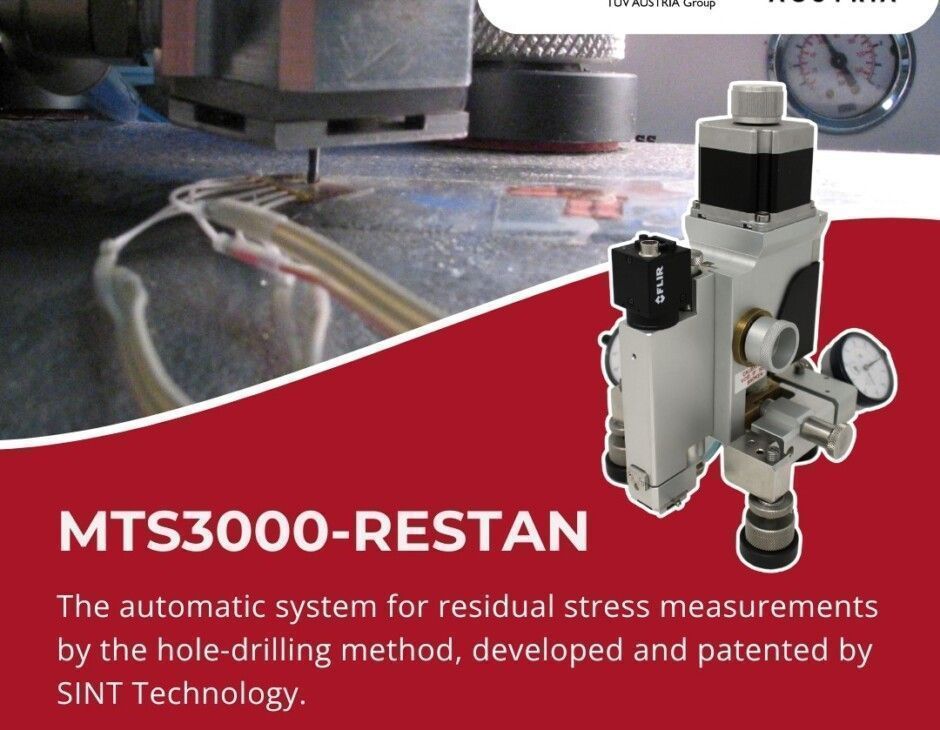

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

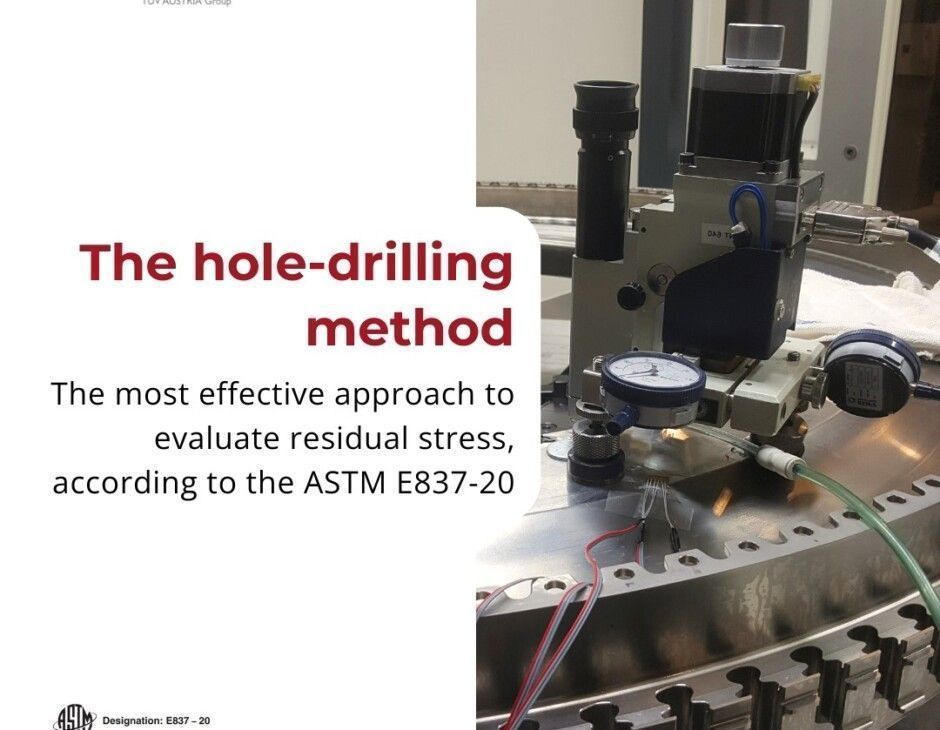

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

Cooperation

SIListra Systems GmbH, a highly specialized software company, and innotec GmbH, a consulting company specialized in Functional Safety, announced their strategic partnership to improve the safety development of embedded systems. The collaboration brings together SIListra’s cutting-edge software tool, the certified SIListra Safety Transformer, and innotec expertise in functional safety solutions, aiming for a holistic approach to functional safety.