From standard tests to complex research projects. TÜV AUSTRIA TVFA – Austria’s number one in component and material testing delivers efficient solutions for new opportunities and more entrepreneurial success. As part of the TÜV AUSTRIA Group, the company offers a wide range of solutions together with the testing laboratories at the Technology & Innovation Center in Vienna.

Efficiency in the mobility of people and goods is one of the most urgent issues for our economy, despite digitalisation, the consequences of pandemics, war and political upheaval. In addition, there are fundamental changes in the way we live and consume. All of this requires new solutions and new technologies for transport systems on the road, rail or in the air. At the same time, it provides an attractive environment for market players inside and outside Europe.

One of the most profound changes concerns the shift in propulsion technology in transportation, followed by the expansion of public transportation and the multimodal use of everything from rental bikes to autonomous vehicles. Drones represent a unique and unfamiliar form of transportation for the population. Currently, the developments are still focused on rescue organizations and small transports, but work is being done intensively on their use in classic mobility. The pressure on industry to develop new solutions quickly and offer tailor-made solutions for transport network operators is enormous.

To be able to sustainably compete in the market, products must meet the highest demands – in terms of safety, availability, maintainability, compliance and performance. Technologies that are not yet part of the standard program, such as additive manufacturing, monitoring systems or AI, bring additional challenges for all market participants.

Electrical engineering, material testing, environmental simulation

TÜV AUSTRIA offers tailor-made testing concepts for these challenges in the areas of mechanics, electrical safety, electromagnetic compatibility (EMC), environmental simulation and IT/OT security. At the TÜV AUSTRIA Technology & Innovation Centre in Vienna, our experts develop individual solutions for a wide range of testing tasks in the mobility industry. The connected service offering of the TÜV AUSTRIA Group optimizes project effort in terms of time and logistics, reduces complexity by providing a single point of contact and reduces overall costs. This enables us to help our customers successfully bring new products to market quickly.

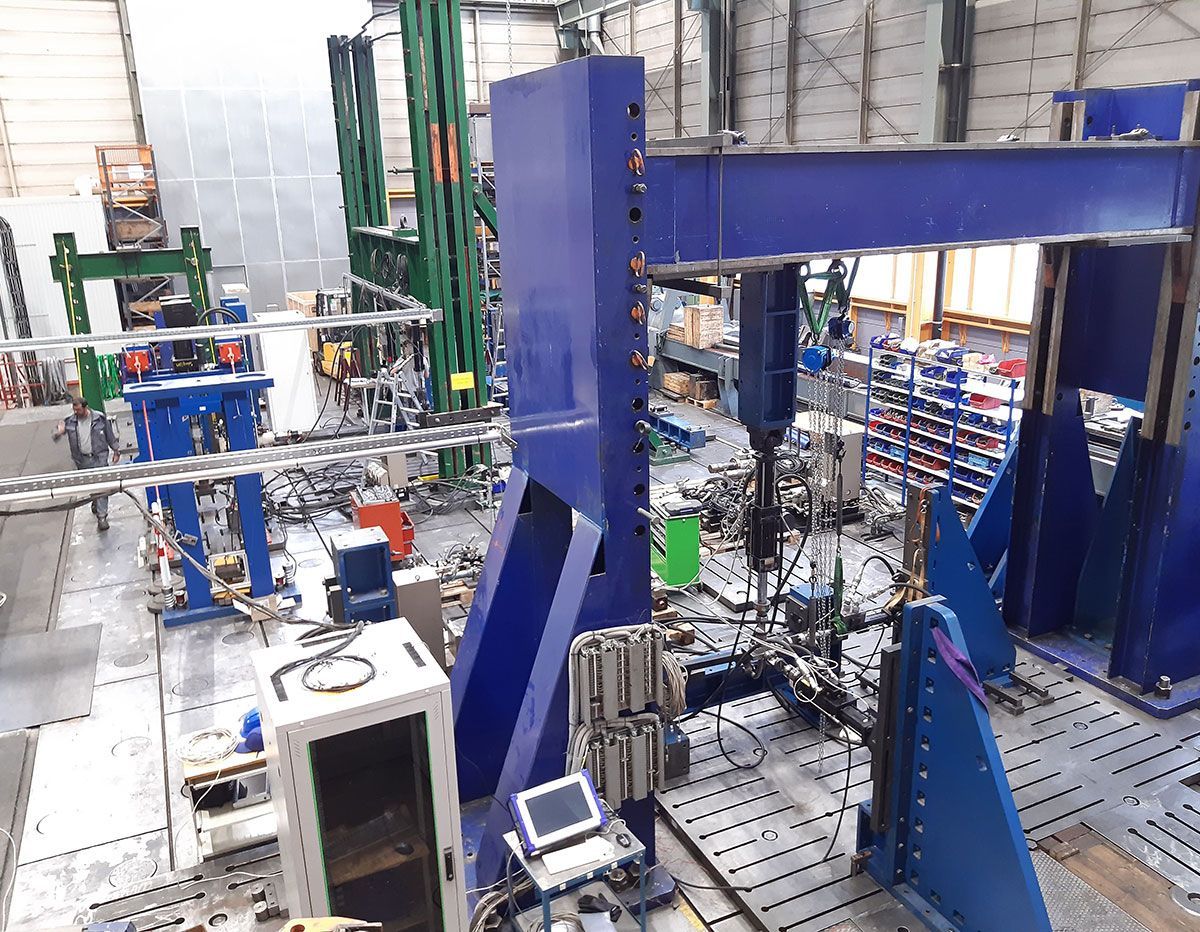

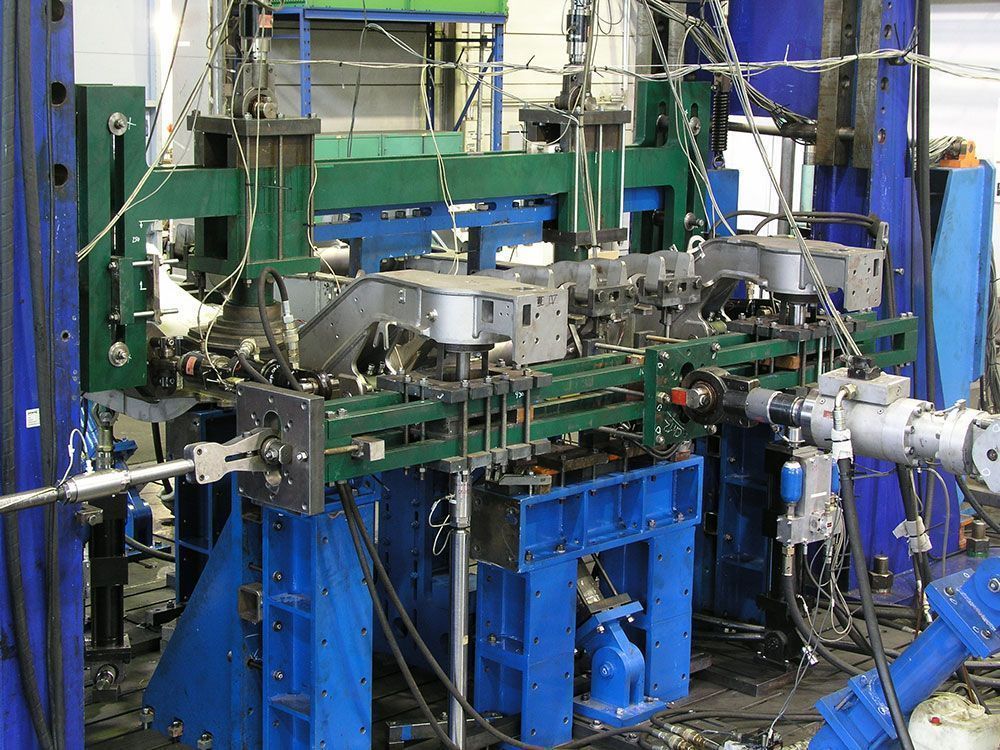

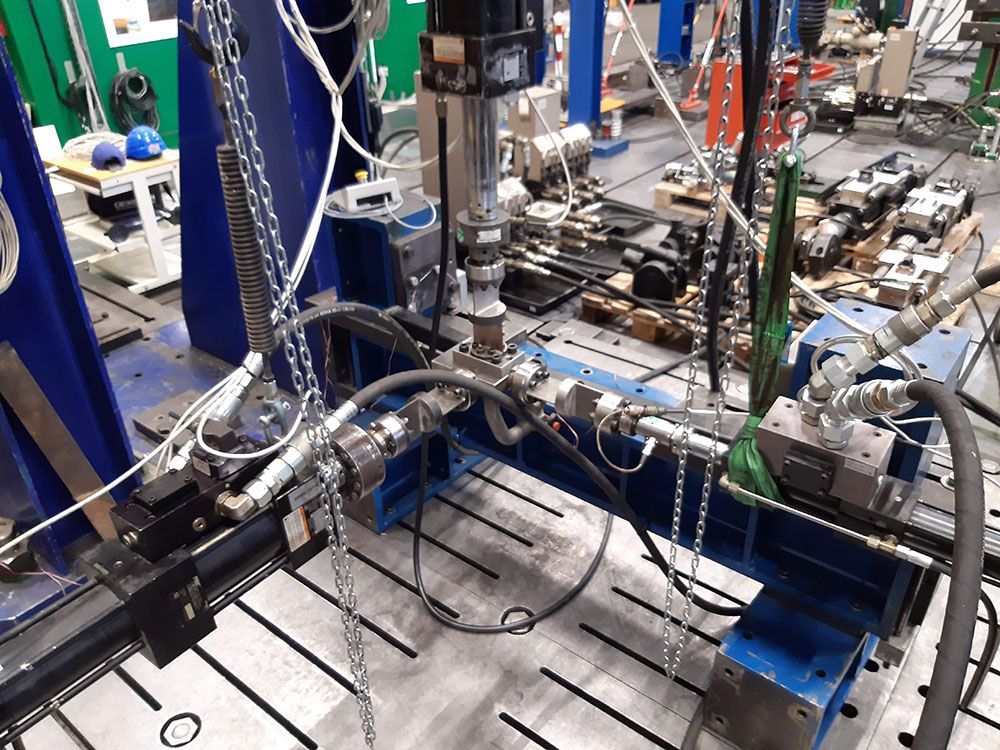

TÜV AUSTRIA TVFA is a leading provider of mechanical component and material testing. Our accredited testing labs can perform both static and dynamic testing on components ranging from small ones to large and complex structures. We design the appropriate test program according to the standard or the specifications of our customers.

In classical materials testing, TÜV AUSTRIA offers the whole range up to fracture mechanics examinations and the currently most powerful industrial computer tomograph in Austria. In the field of EMC, we support you with a broad portfolio of tests in one of the largest EMC test halls in central Europe. The possibilities include the network simulation of all on-board networks as well as e-mobility requirements from AC and DC up to 1 MW as well as battery simulation of all common standards.

In the near future, drive-in climate halls for simulating environmental conditions down to -70°C, controlled humidity, IP protection tests and acoustic measurements will be put into operation.

The combination of research expertise and many years of practical experience has one goal: to open up new possibilities for customers and partners with a broad service portfolio. This not only increases innovative strength, but also boosts competitiveness and is an important contribution to quality assurance.

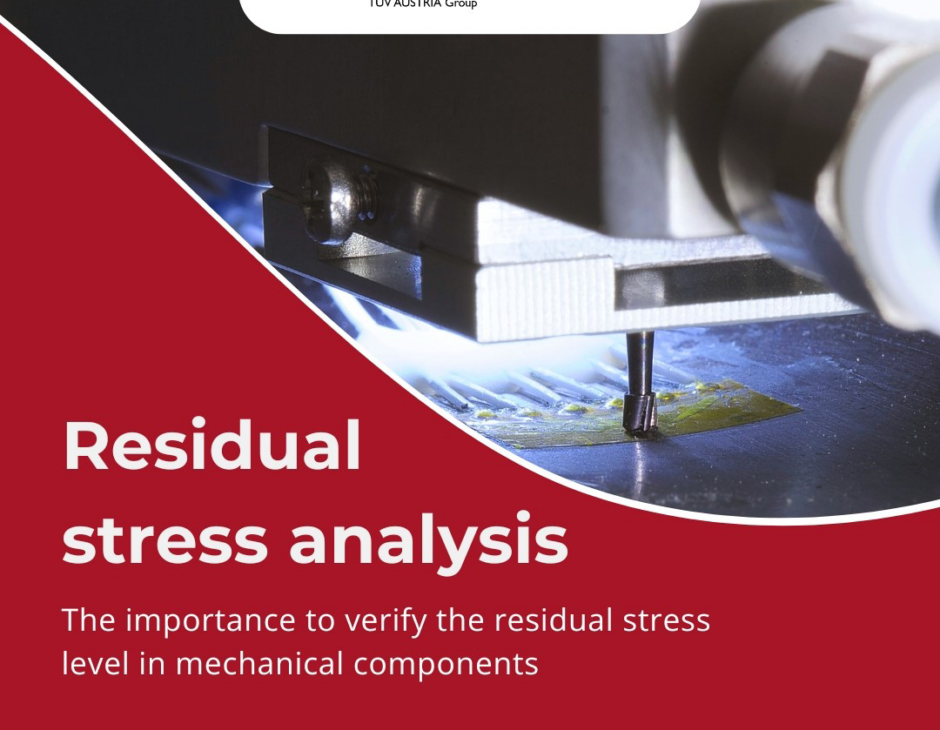

Residual Stress Analyzer

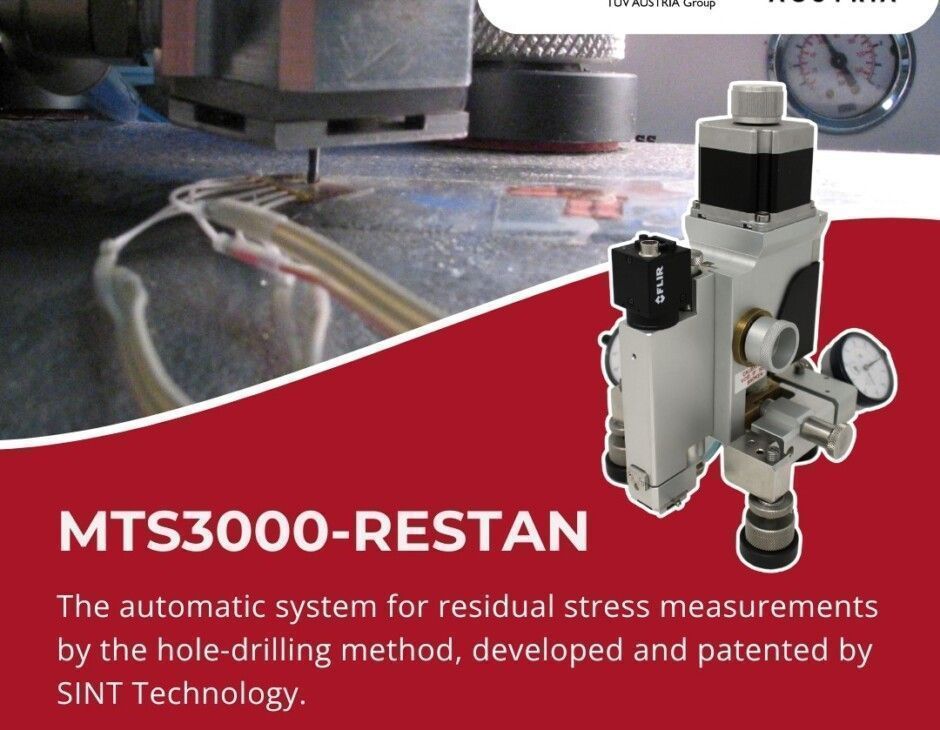

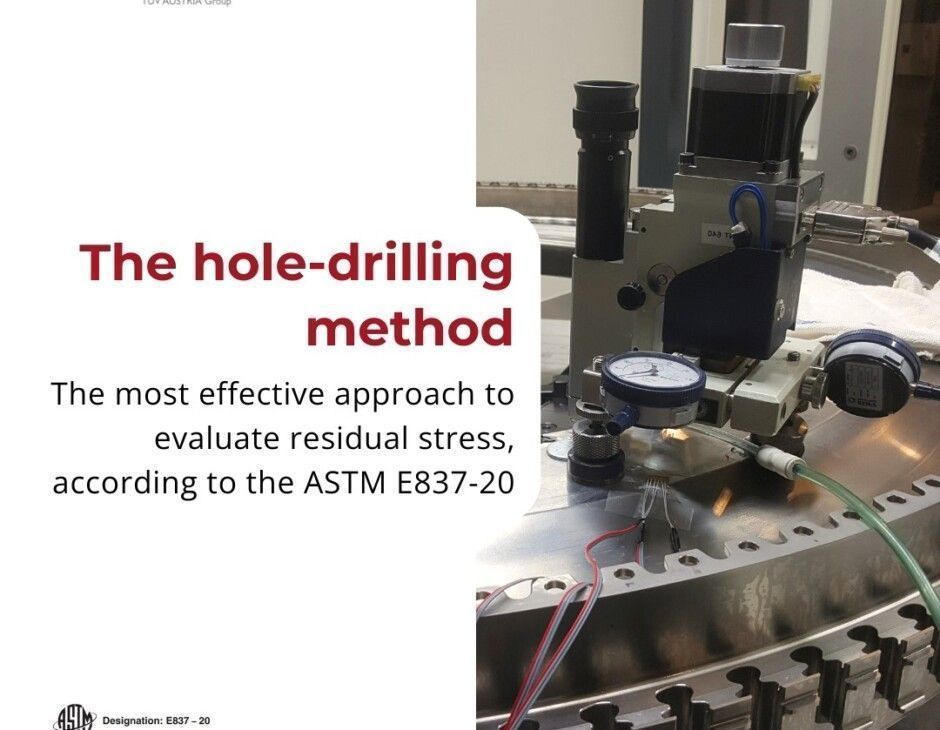

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

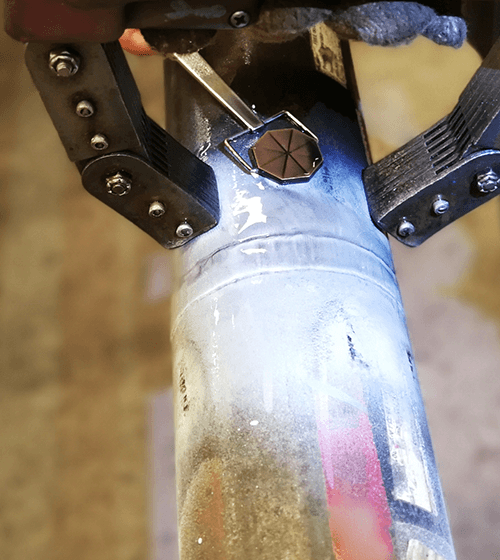

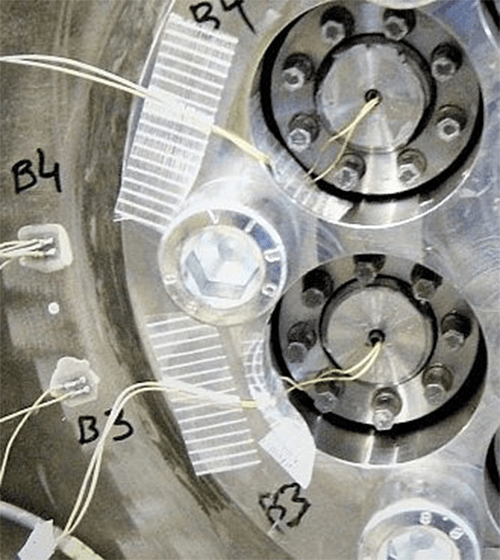

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.