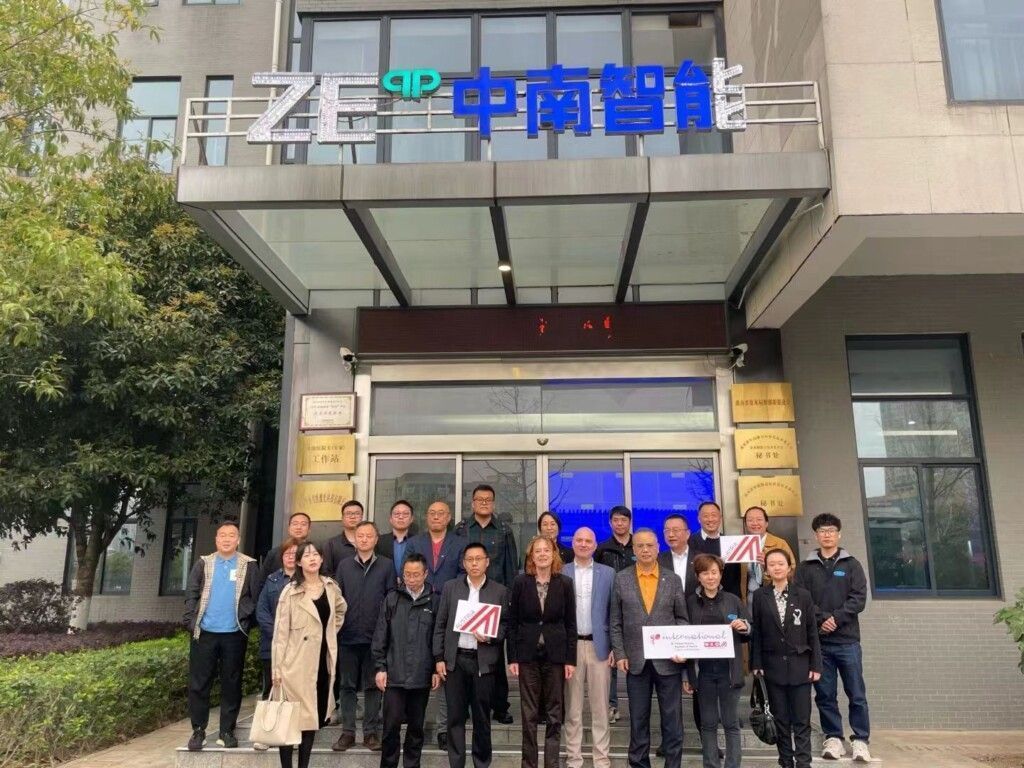

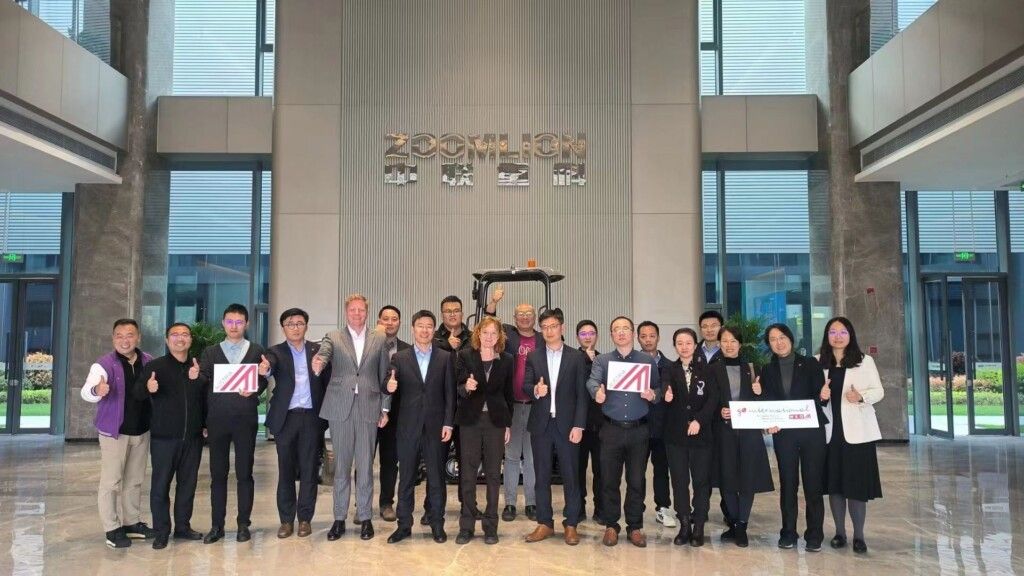

The primary objective of this activity was to gain a comprehensive understanding of the current situation and development trends in the intelligent manufacturing industry in Central China. Additionally, it aimed to facilitate business collaboration and exchange between TÜV AUSTRIA and local enterprises. In particular, the overview, results and contributions of this event include the following aspects:

- We have had a great opportunity for on-site visits to leading local enterprises, including Sany Group, Zoomlion Heavy Industry, CRCHI, CRRC(Zhuzhou), Hunan Iron & Steel, Pusisat, BYD Changsha Factory, Hunan Zhongnan Intelligent Equipment, China Railway Science & Technology, Fiberhome Group and other well-known local enterprises, among others, gaining firsthand insight into their technologies, product lines, and future prospects.

- Through meetings with enterprise management, we initiated discussions on potential collaborations, presenting TÜV AUSTRIA’s capabilities and services.

- We expanded our business network and get in contact with the Hunan Council for the Promotion of International Trade, Hubei Investment Promotion Bureau, Hunan Chamber of Commerce and Hubei Chamber of Commerce. Participated in two business meetings and gained insight into the operations of numerous enterprises in Central China.This will facilitate the establishment of a platform of cooperation and Central China resources for future business development, providing support and convenience.

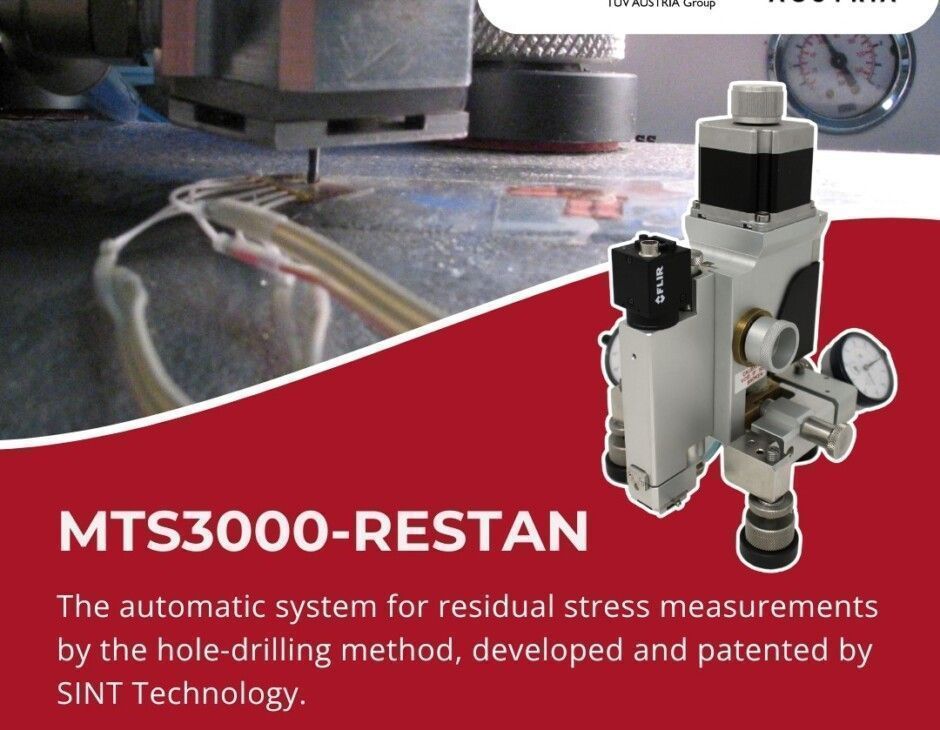

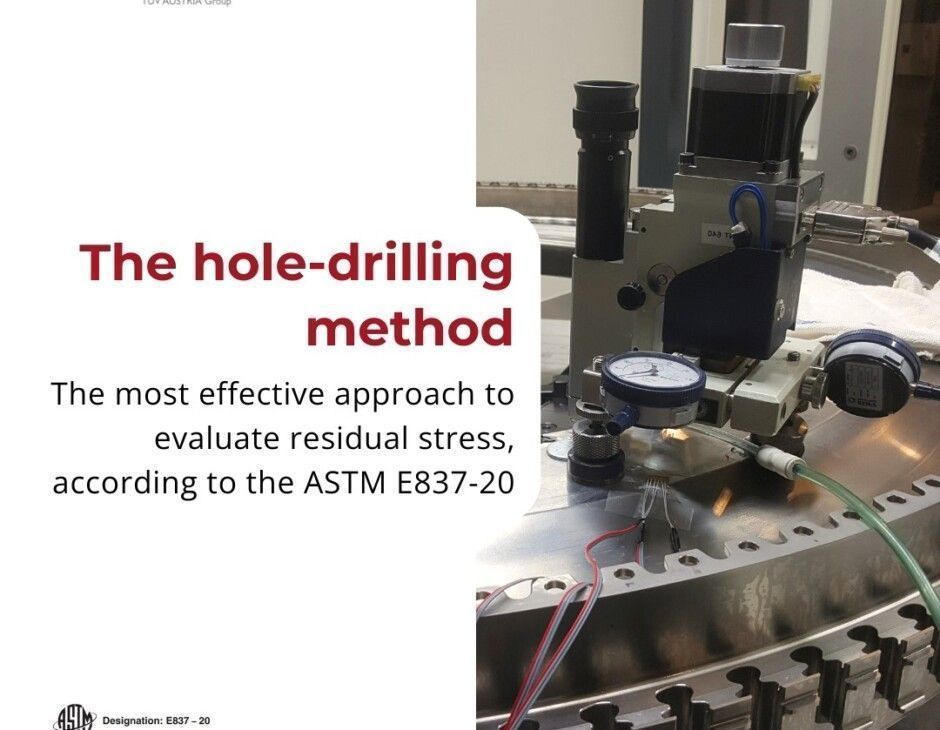

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

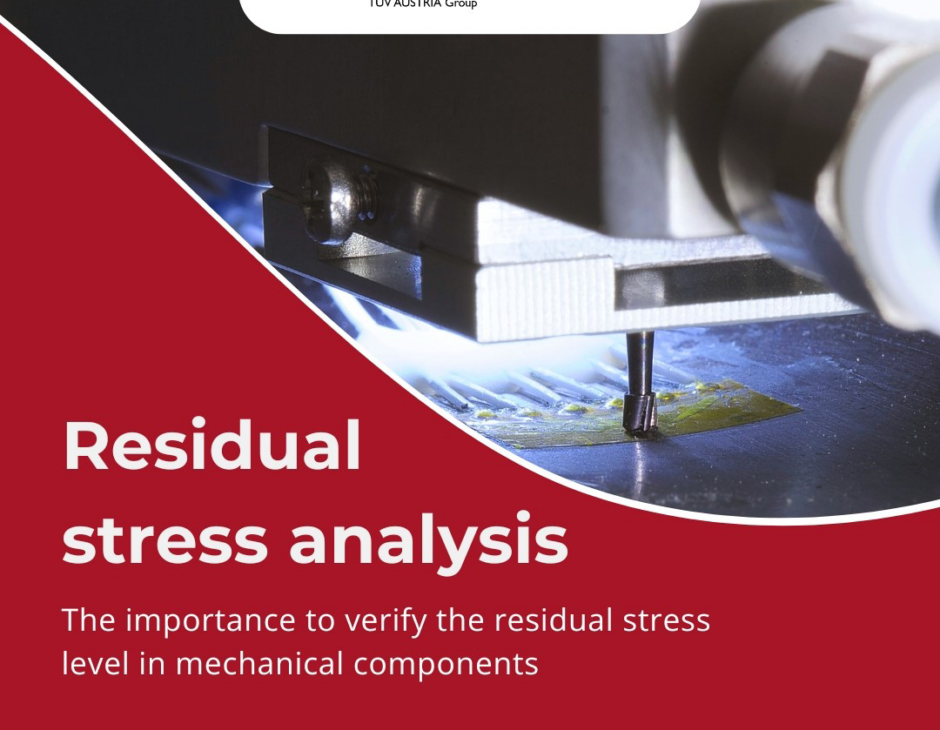

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

Cooperation

SIListra Systems GmbH, a highly specialized software company, and innotec GmbH, a consulting company specialized in Functional Safety, announced their strategic partnership to improve the safety development of embedded systems. The collaboration brings together SIListra’s cutting-edge software tool, the certified SIListra Safety Transformer, and innotec expertise in functional safety solutions, aiming for a holistic approach to functional safety.