On November 1, 2023 IVT Inspections NV has become part of the TÜV AUSTRIA Group. IVT Inspections NV started in 1993 initially with camera inspections and thermographic cameras. Soon they bought the first IRIS system at the request of their customers. At the time, it was still an analogue system. Since the early days they serve as critical service provider during turn arounds in the petrochemical and chemical sector. Steadily over the years the customer base has grown to five IRIS teams. Further since the early 90’s IVT was assigned to visually inspect welds in clean pipe systems at pharmaceutical companies with their specialized video endoscopes.

Over the years the investments in specialized endoscopes has continued and currently there is a wide range of diameters and lengths up to 10 metres. And it does not stop with endoscopes, there have investments in several camera systems for pipeline and tank inspection with both ATEX and non-ATEX systems and drones for the visual investigation of confined space.

Additional NDT Service

With the addition of IVT Inspections NV to the Non-destructive testing-team, now TÜV AUSTRIA Belgium can offer the complete scope of NDT and Advanced NDT in the Industrial Life Cycle of Installations, ranging from corrosion studies including autoclave expertise, Vlarem, PED and Risked Based Inspections.

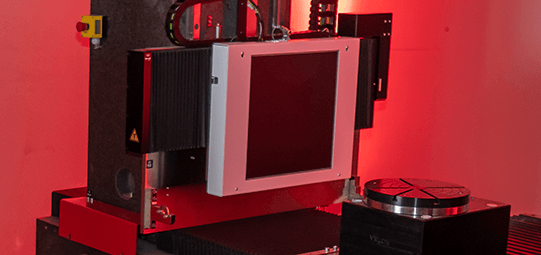

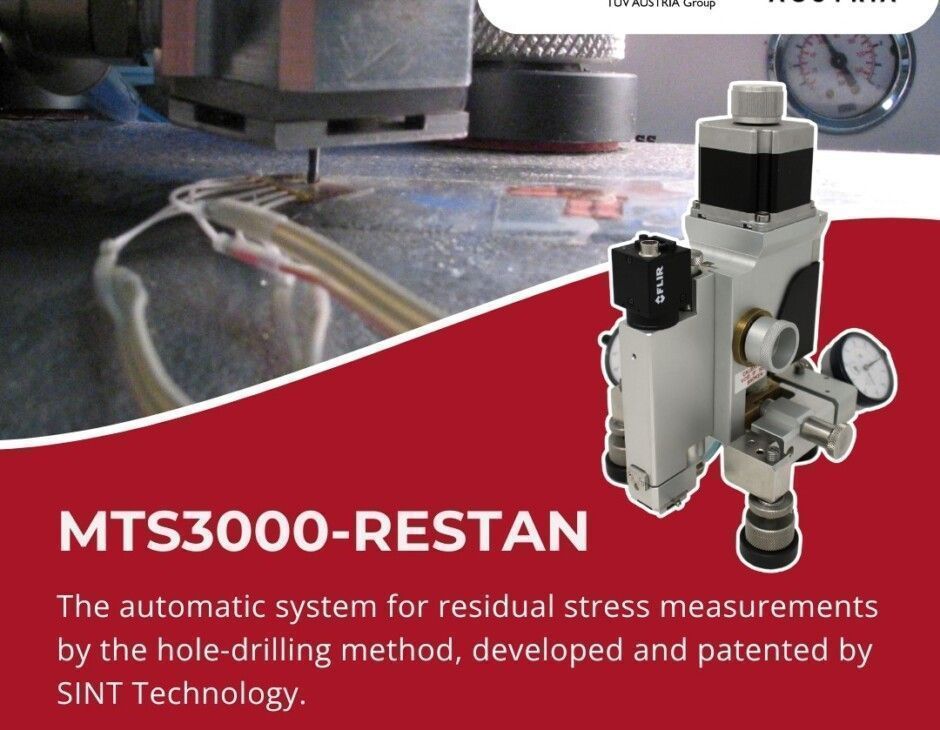

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

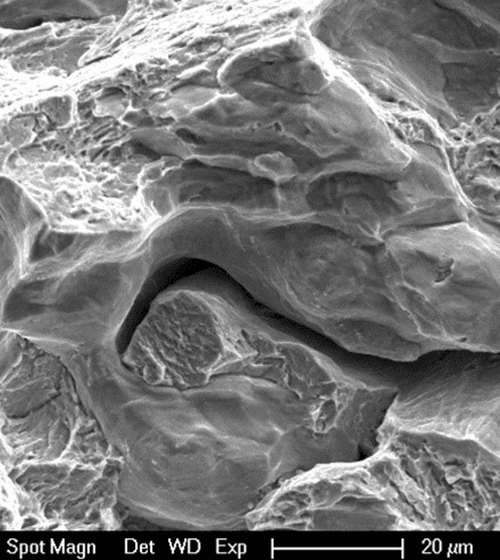

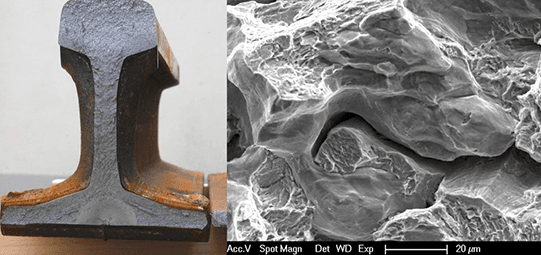

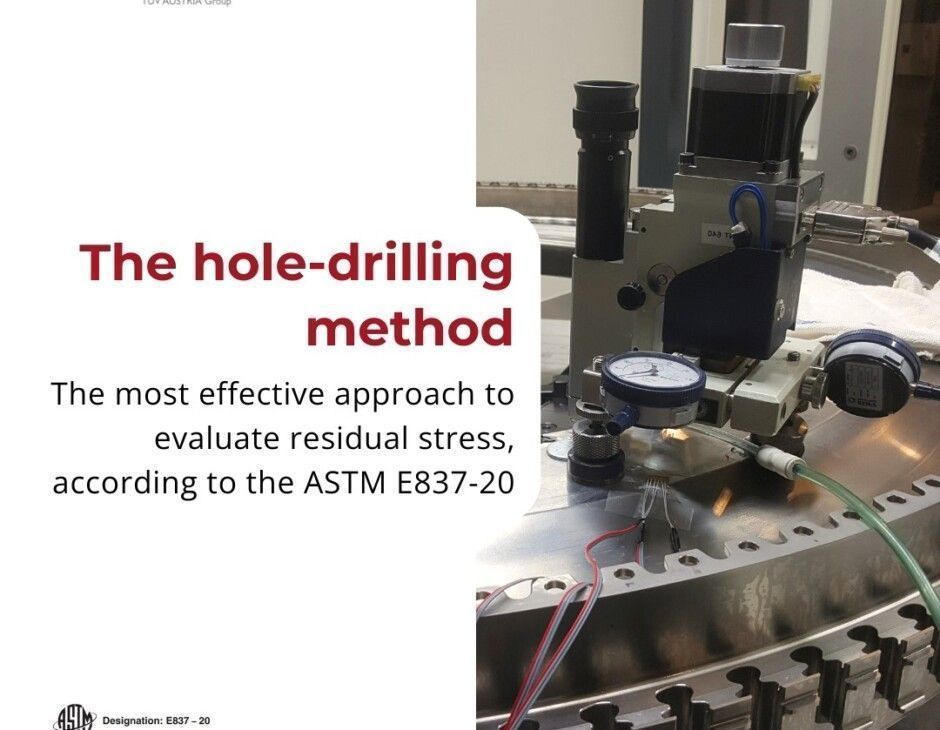

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.