Alumil is the first company in Greece to receive the TÜV AUSTRIA “OK Recycled” certification to produce aluminum profiles from 60% recycled aluminum raw material!

Committed to the principles of sustainability and circular economy

Alumil, with more than 30 years of experience and 2.200 employees, is one of the most advanced companies in the design and production of architectural aluminum systems worldwide. At the same time, all 12 factories in Europe possess the most modern production lines. For many years, Alumil’s business strategy has been based on the principles of sustainability and the circular economy, taking steady and decisive steps towards reducing its environmental footprint.

One of these was the creation of the state-of-the-art aluminum scrap sorting and processing plant at its premises in the Industrial Area of Kilkis, Greece. Its pioneering unit makes a significant contribution to meeting its environmental objectives, as it is used to produce aluminum from recycled raw material.

With the “OK Recycled” certification, Alumil demonstrates in practice that the manufacturing excellence they strive for is not only an end, but the means to realize their vision: improving the quality of people’s lives, which is interconnected with the quality of the natural environment .

Reliable and objective representation of the recycling percentage

The OK Recycled certification scheme is based on quantification of mass balances and coordinated traceability of the recycled content of a product or group of products. It is applicable to any type of material (e.g. plastic, aluminium, fibres, paper) and any product that uses recycled material in its production. The benefit of OK Recycled lies in ensuring that the information on the recycled content of the product in question is reliable, objective and easily identifiable.

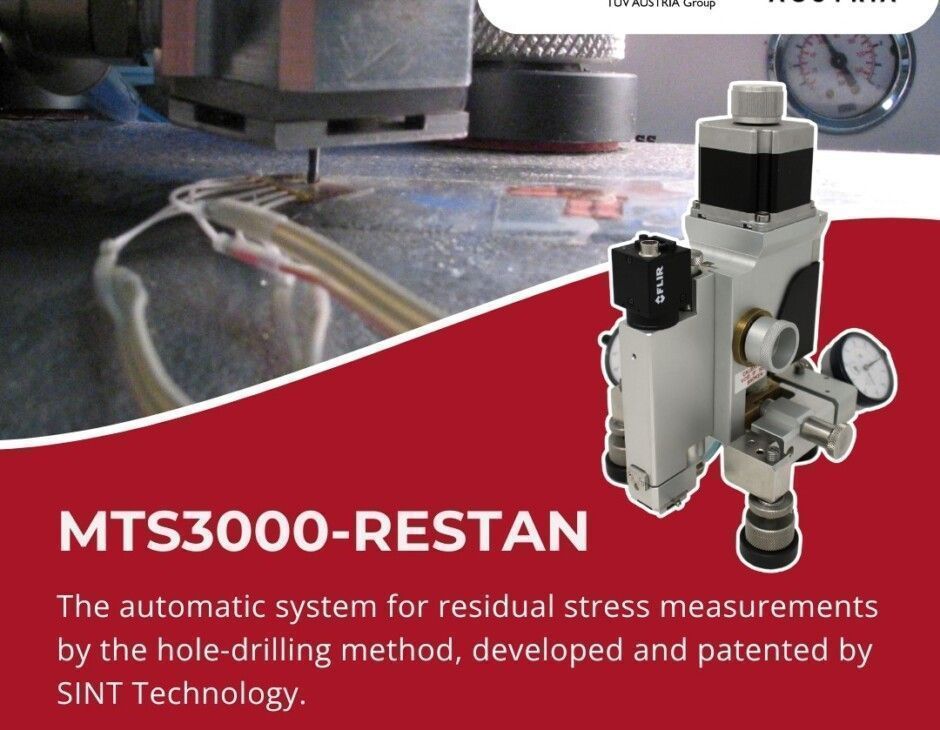

Residual Stress Analyzer

SINT Technology, a member of TÜV AUSTRIA Group, produces the MTS3000-Restan. An automatic system to perform the ASTM E837-20 procedure by hole-drilling.

TÜV AUSTRIA Shanghai

Austrian Delegation:

Smart Manufacturing Business Mission

TÜV AUSTRIA Shanghai participated in the Smart Manufacturing Business Mission to Central China, organised by the Commercial Section of the Austrian Consulate General.

TÜV AUSTRIA Shanghai

Canton Fair:

Showcase of TÜV AUSTRIA’s expertise and services to a global audience

The 135th Canton Fair, revered as “China’s first exhibition”, provided a platform for TÜV AUSTRIA to showcase the expertise and services to a global audience.

Cooperation

Modelwise and innotec

Partner to Innovate Functional Safety

Modelwise, a spin-off of the Technical University of Munich that develops software for automated functional safety analyses, and innotec GmbH, a consulting company specialized in Functional Safety and since 2020 part of the TÜV AUSTRIA Group, announced their strategic partnership to innovate functional safety assessment. The collaboration combines Modelwise’s innovative software tool Paitron, applicable for all (A)SILs according to IEC 61508 and ISO 26262, and innotec’s expertise in functional safety solutions including HARA, safety requirements management, and safe hardware and software development.

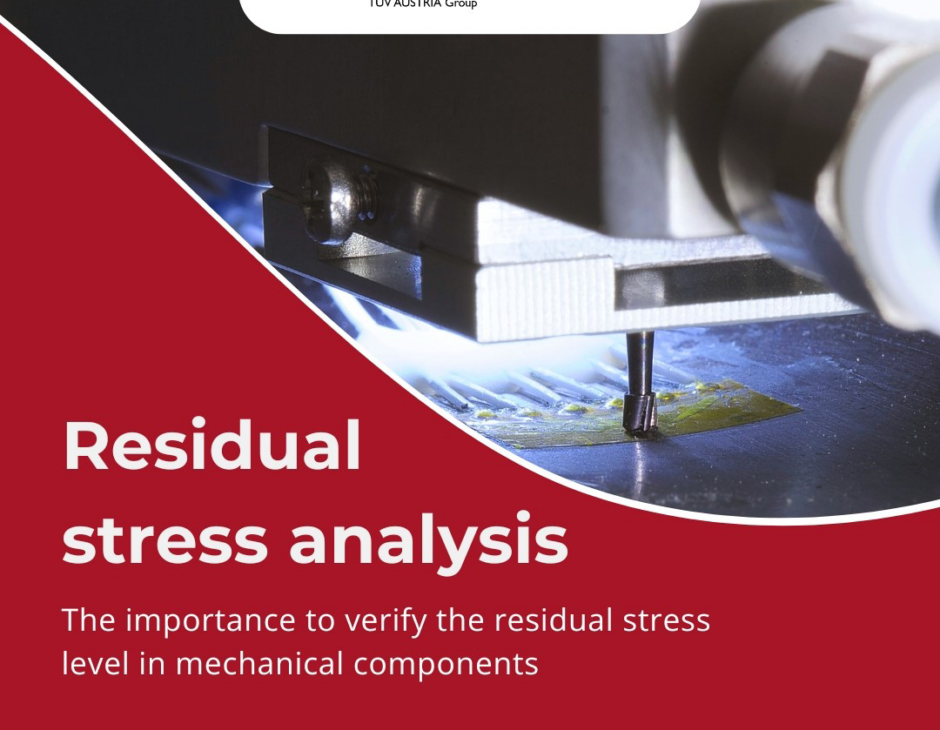

SINT Technology

Residual stress analysis in mechanical components

With state-of-the-art measurement technology

SINT Technology, a member of TÜV AUSTRIA Group, uses state-of-the-art measurement technology to test the residual stress level in mechanical components.

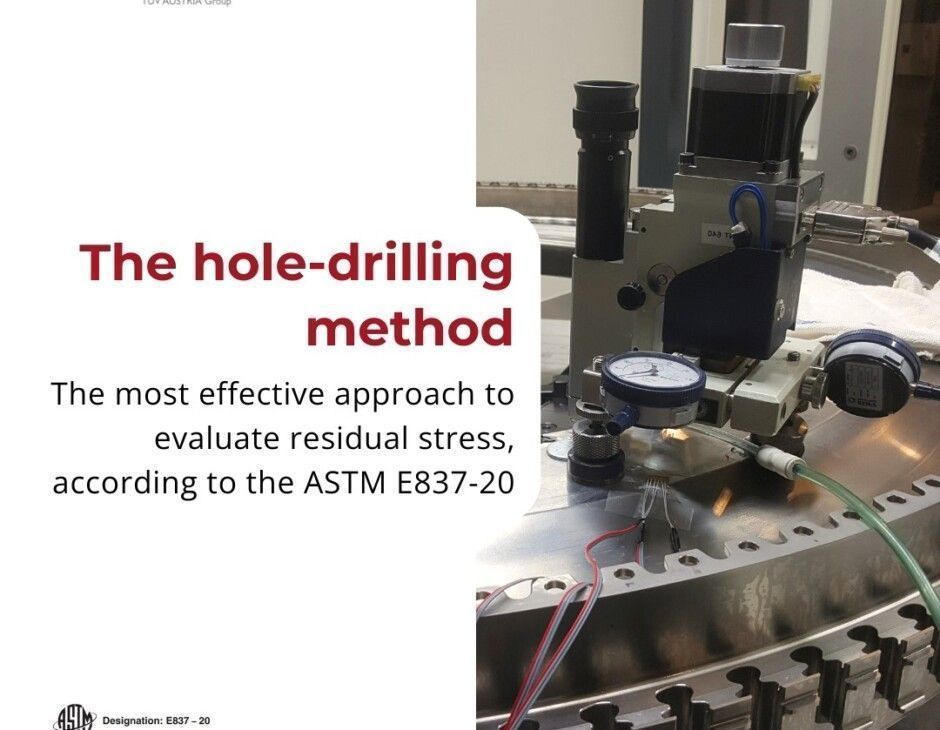

SINT Technology

Hole-drilling-method

Non-destructive mechanical method for residual stress analysis

SINT Technology, a member of TÜV AUSTRIA Group, uses the non-destructive mechanical method for residual stress analysis.