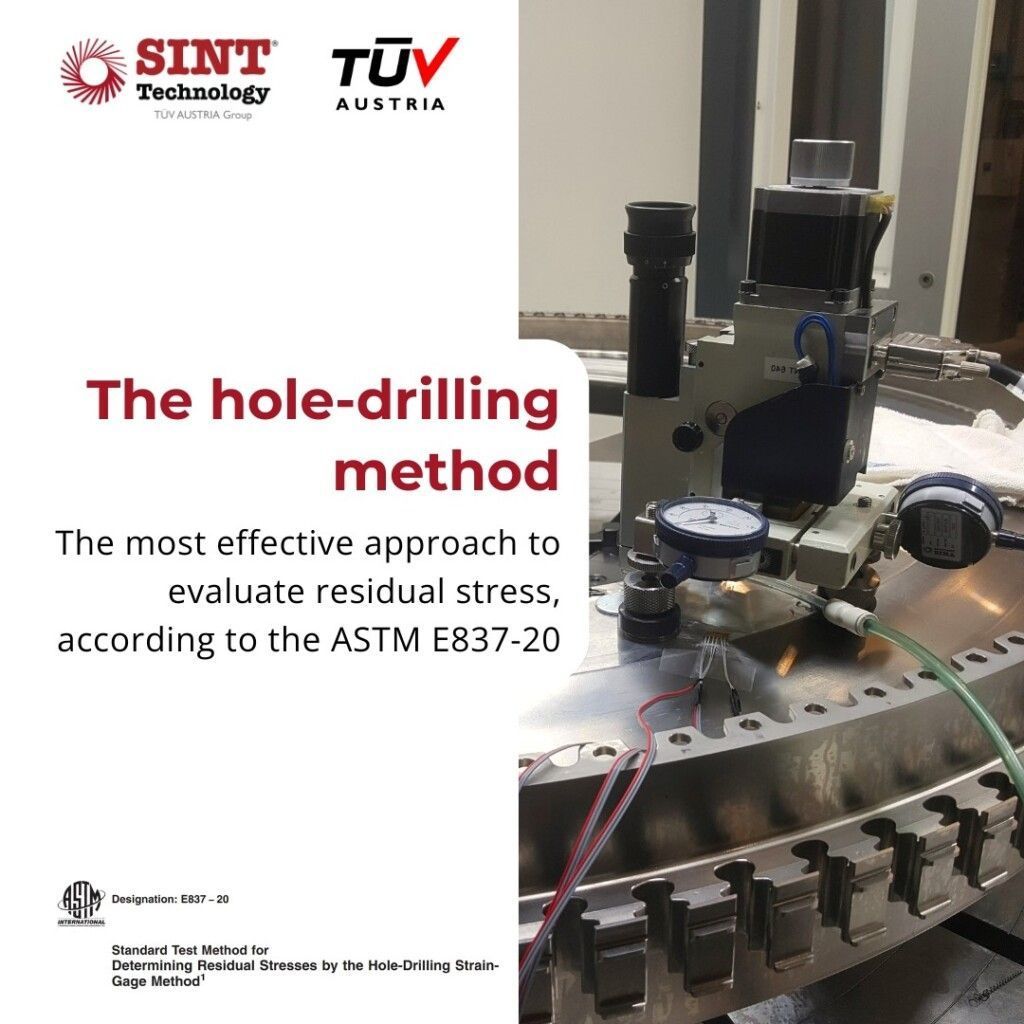

The hole-drilling method is a semi-destructive mechanical method to measure residual stresses using strain gage rosettes and it has been standardized at world level by the ASTM E837-20 “Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method”.

The hole-drilling method is the most effective approach to evaluate residual stress thanks to the following features:

- High precision

- Low damage

- Field use

- Stress profile along the depth

- Quick stress profile

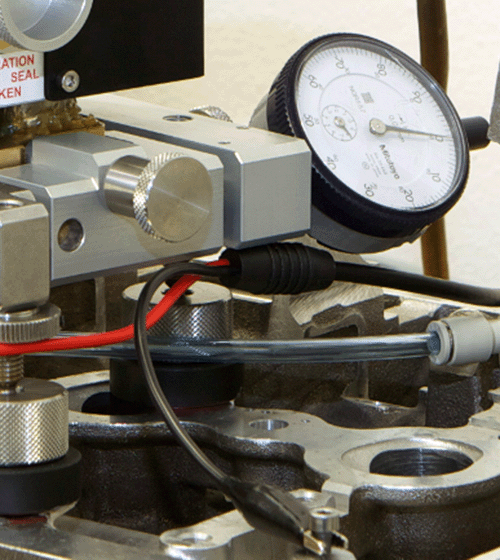

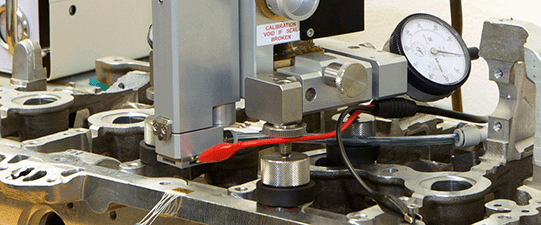

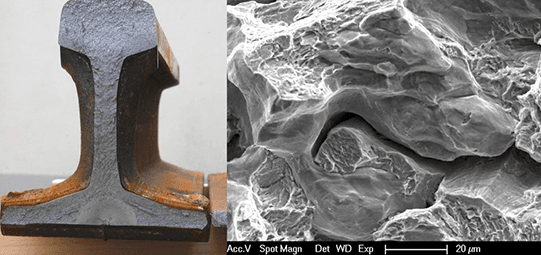

The MTS3000-Restan by SINT Technology is an automatic system to perform the ASTM E837-20 procedure by hole-drilling. With this method, a small hole is drilled in a stressed specimen, thus producing strain relaxations in the material surrounding the hole. These relaxed strains are acquired from the rosette and then used to calculate the magnitude and the direction of the residual stresses using the calibration coefficients supplied by the standard.

The ASTM E837-20 specifies the following parameters that are typically used in a hole-drilling test:

- The limit of applicability

- Analysis depth

- Calculation algorithms

- Drilling increments

- Numerical coefficients

- The data processing method

For the hole-drilling technique, SINT Technology is an ISO/IEC 17025 accredited test lab according to the ASTM E837 standard. The company also produces the MTS3000, fully automatic machine for measuring residual stresses by hole-drilling. More information: